Reducing costs and improving output of finished fuels by smart filtration

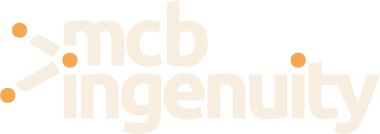

Patented molecular sieve selectively binds to targeted compoundsTypical HDT Arrangement

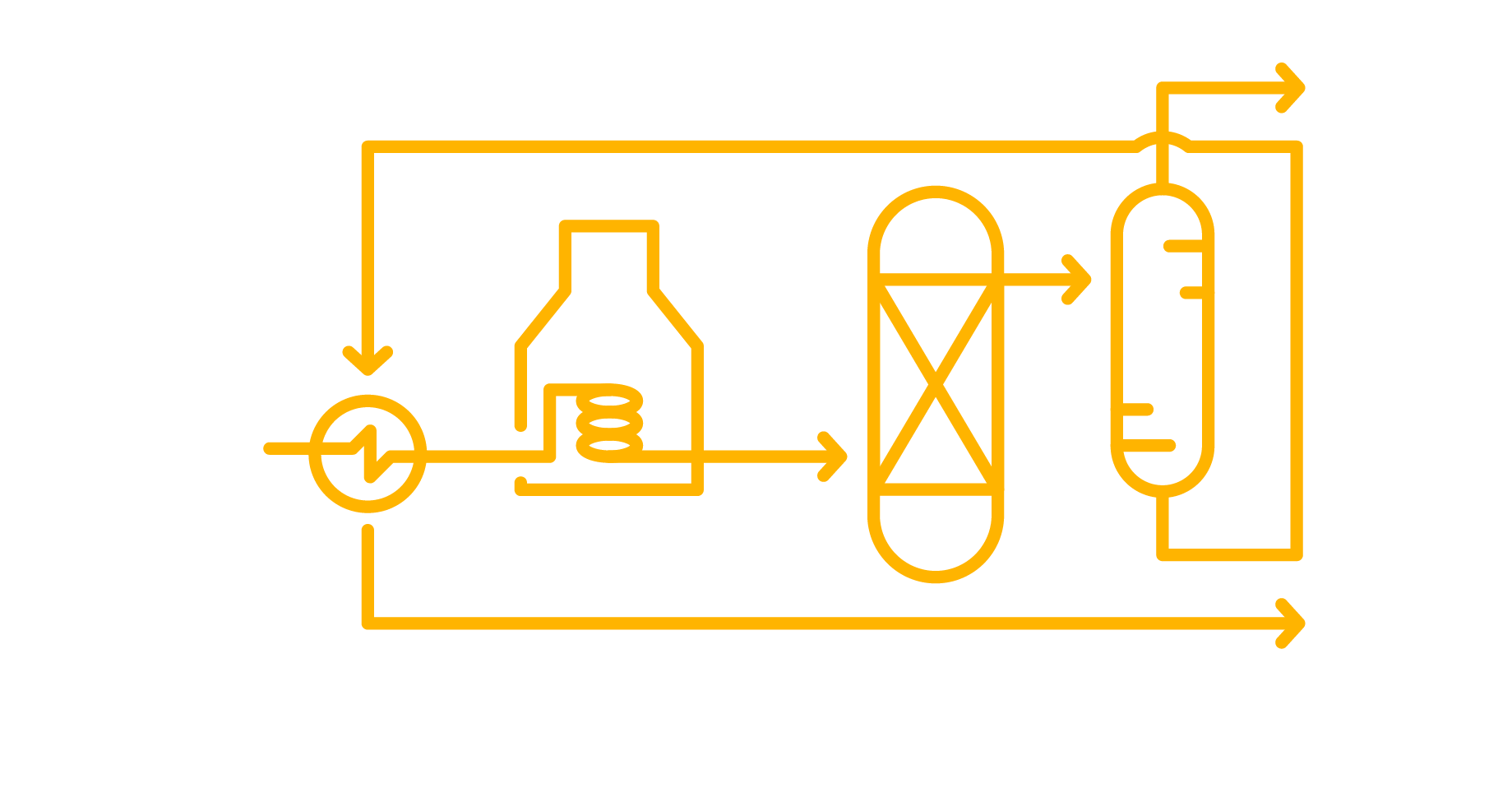

HDT with

Back-End Molecules Sieve

The Problem

Hydrodesulfurization capacity can often limit total refinery throughput due to its high energy intensity and increasingly stringent fuels sulfur specifications.

Furthermore, precious metal catalysts are costly and have a limited lifespan. MCB Ingenuity offers a solution to not only alleviate strain off this existing system reducing sulfur extraction capex and opex, while increasing output of finished fuel’s by 5-10%.

Our Technology

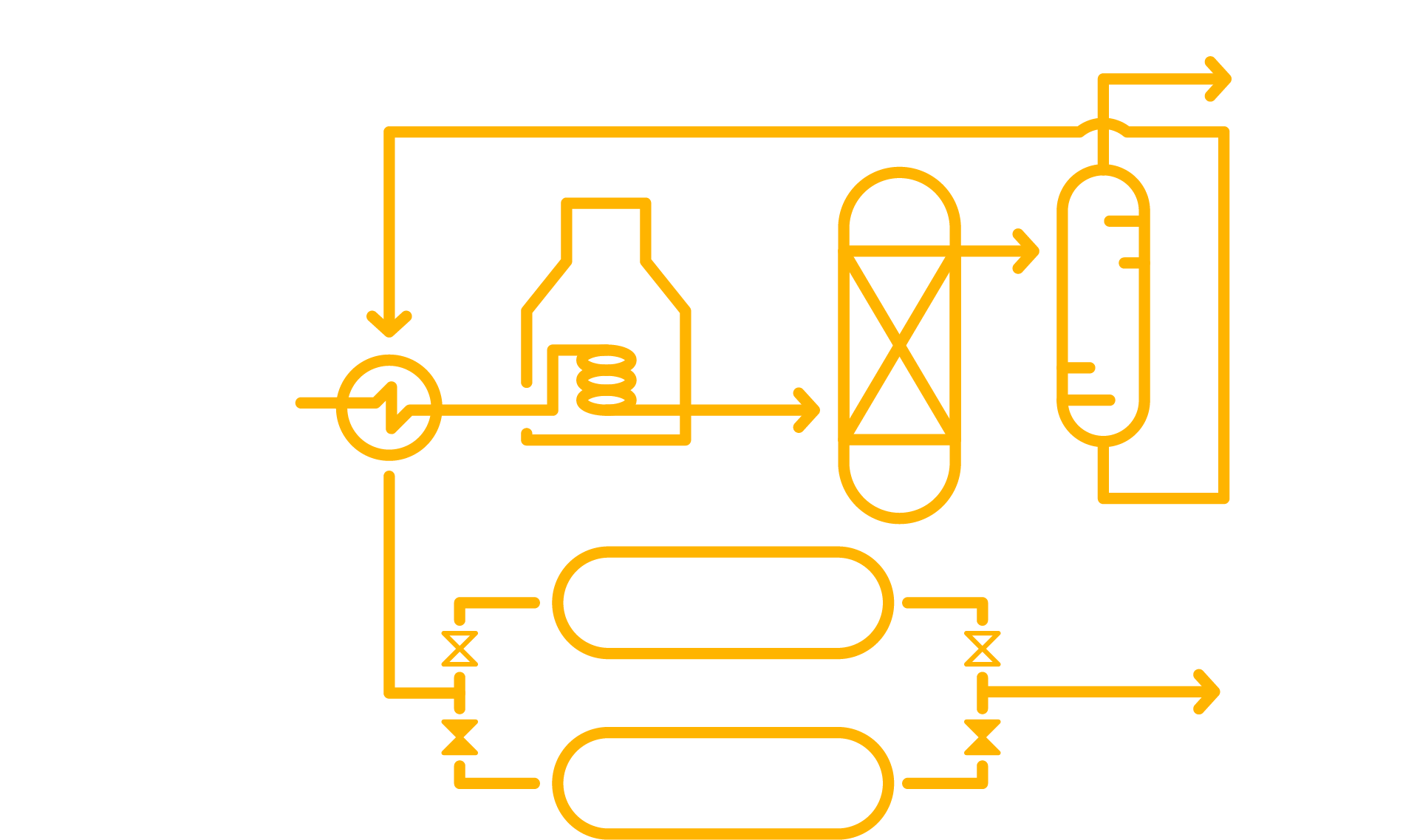

Instead of physically extracting the sulfur resulting in high running costs, MCB Ingenuity selectively targets sulfur using a molecular sieve to alleviate strain on the hydrotreater while still meeting targets of 15 ppm or less in ultra low sulfur diesel. MCB Ingenuity has two patents on a unique molecular sieve, which is made of a long backbone and active binding sites

Traction to Date

Two (2) patents approved and issued in Canada and US.

3rd party confirmation of sulfur reduction in finished diesel fuel by up to 60%.

Other iterations of the molecular sieves have demonstrated selective removal of other chemicals such as nitrogen groups, long chain hydrocarbons, bis phenol A (“BPA”), bulky groups (hormones), and pharmaceuticals.

Watch our video for more information about MCBI’s novel technology.

Investor Relations

MCB Ingenuity is seeking equity investors to commercialize the molecular sieve.

Funds are required for: